Capabilities

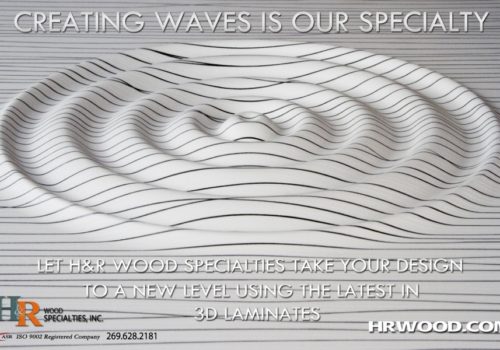

H&R is a full service component manufacturer and offers our clients access to the latest in processing equipment and expertise:

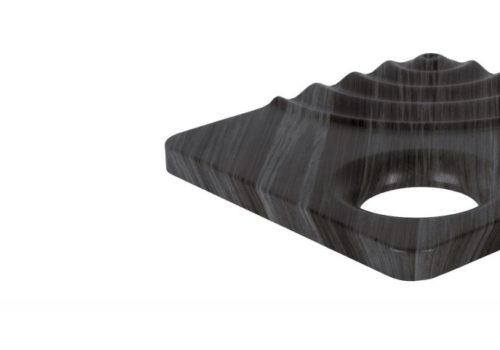

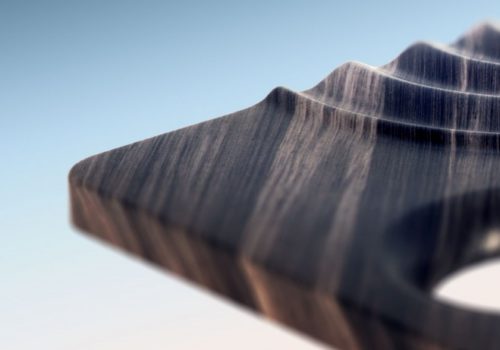

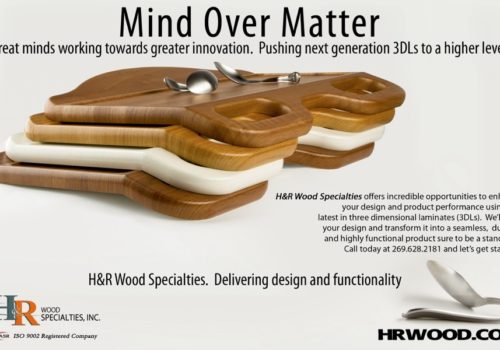

- High and low volume Membrane pressing

- 4- axis multi-head CNC machining

- Fulfillment services

- Assembly/fabrication

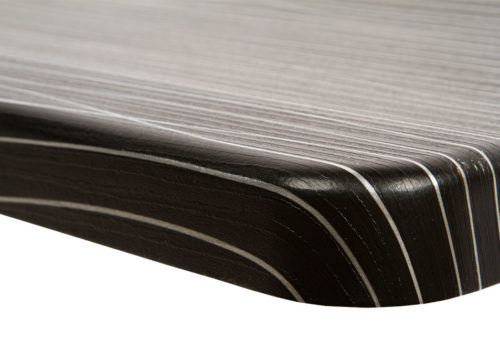

- Contour edgebanding

- Project Management

- Engineering/Design

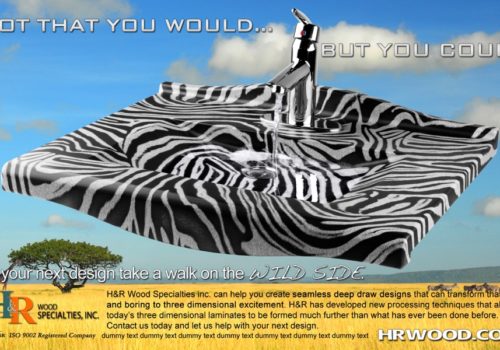

Included in our list of capabilities is the foundation of our business. H&R supports our clients with five high production presses offering up to 12 foot long and 5 foot wide capacity. Each press is unique in its own way which offers more processing options to accommodate a wide range of design applications for any job size.

As an industry leader, H&R sets the gold standard in capabilities and resources ensuring even our smallest clients the ability to offer products in a big way.

Eco-Friendly

H&R is always committed to our environment and only partners with raw material suppliers that are actively refining their materials to lower the impact on our planet. Our clients are finding products we produce for them qualify for LEED point certification and are also meeting or exceeding CARB II compliance minimums.

MDF (medium density fiberboard) is a highly refined wood substrate typically used as the base material for most of the products we manufacture. MDF not only makes an excellent substrate but is considered environmentally sound as it comes from 100% recycled or recovered wood fiber. In other words, no living trees are cut down to produce our wood substrates.

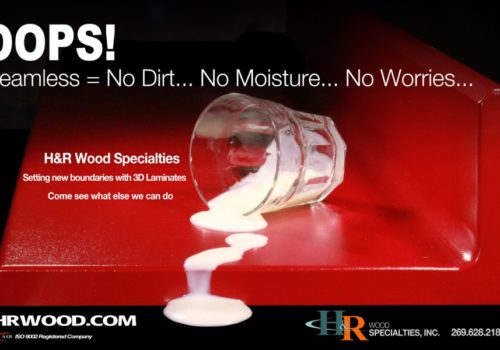

Clean

Our unique process of 3D laminating provides our clients the opportunity to offer products with virtually no seams. Whether it is on the edges or in the middle of the component, any surface covered with 3D laminate is essentially sealed eliminating exposing any part of the wood substrate to the outside environment making those areas impervious to moisture penetration. Without those areas of penetration, dirt and bacteria have no chance in finding safe haven anywhere on surfaces 3D laminate is used.